NUEVO LEÓN IS THE CLUSTER HEADQUARTERS

The State brings together a numerous clusters that collaborate in company growth and competitiveness

For that reason, since the year 2000, national and foreign companies that have made their homes in Nuevo León began to found citizen councils. They were then formalized into industrial clusters in different productive activities in 2004 to seek progress in the state.

Eight sectors were identified to receive support: the agrofood, aerospace, automotive, biotechnological, nanotechnological, electrical appliance, specialized medical service and information technology and software sectors.

Two more were recently created; one of them is the cluster for interactive and entertainment media and the other one is for the development of sustainable urban development and housing which was formalized this past June.

The formation of those clusters, under the responsible and joint participation of the productive sector, was an important step in the development and consolidation of Nuevo Leon in the economics of knowledge. These clusters that seek to work under the new concept of “coopetency” (collaboration in competition) have developed synergies and economies of scale. With the collaboration of academic and government sectors they have boosted local productivity and competitiveness.

Sergio Pérez, Coordinator of Industrial Groups for the Secretary of Economic Development, pointed out that one of the greatest benefits of belonging to a cluster is specialization since academic and government sectors participate in them, which facilitates activities of the sectors.

Pérez indicated that Monterrey and its metropolitan area are the most competitive zones in the country and the mission of all sectors is to compete not only in Mexico but world-wide.

A cluster with great representation

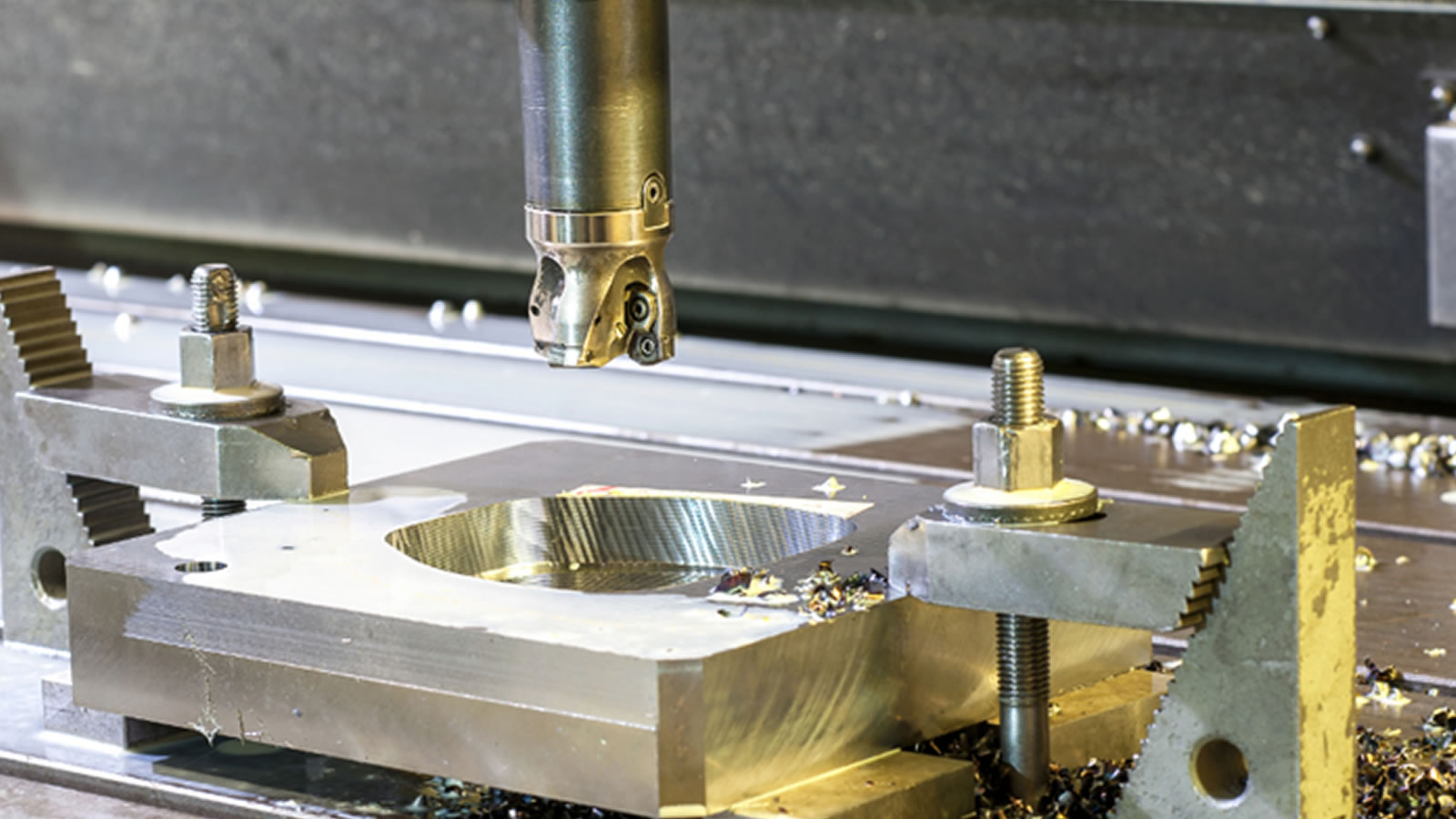

Because the Nuevo Leon holds first place nationally in the production of cylinder heads, motors, car batteries, glass and harnesses and it holds second place in the production of trucks and busses, electrical and electronic equipment, as well as plastic parts for the final automotive industry. It also produces chassis, transmissions, brakes, seats, metal dies, tires, steering and suspension systems, among others, the creation of the Automotive and Automotive Part Cluster was considered necessary.

That agency is formed by approximately 43 companies.

“Our mission is to integrate businesses, universities, technological and research institutes and government organizations to collaborate together and construct a common vision for growth in the competitiveness of the automotive industry in Nuevo León”, stated Fabiola Aguilar Martínez, Coordinator of the Committee for the Development of Suppliers of CLAUT created in 2005.

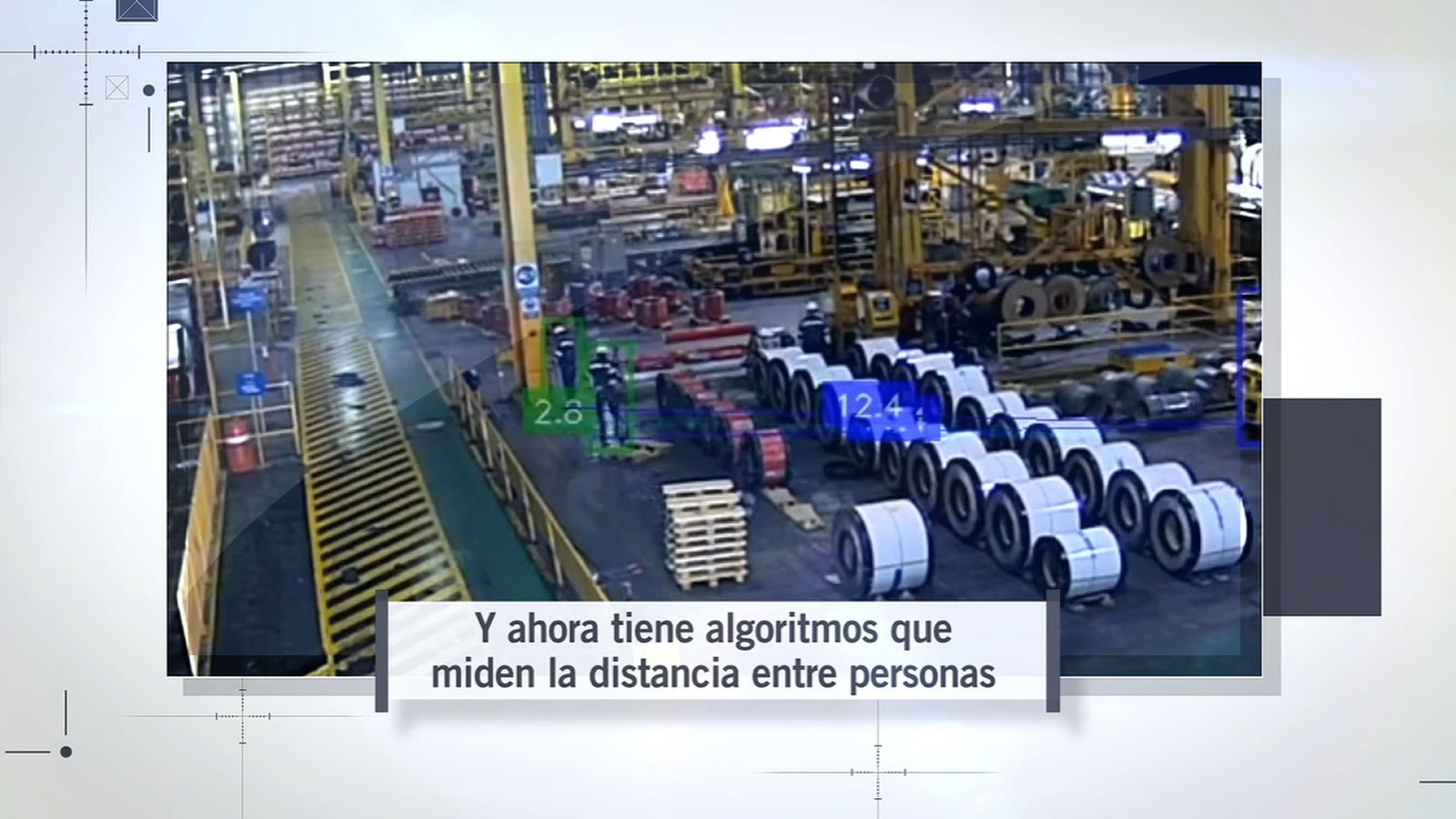

To support competitiveness in this industry, work is now being done on a virtual laboratory and on liaison practices between businesses and universities.

Aguilar emphasized that the cluster is formed by eight work committees that include logistics, human development, development of suppliers, innovation, sustainability and the environment, best practices, finance and small and middle-sized businesses (Tier II).

Aguilar mentioned that the logistics committee is now working on a strategy to increase competitiveness at border crossings, especially at the Colombia Bridge.

On the other hand, the human development committee detected the following need in all of its partner companies: a deficit of technicians in electromechanical maintenance. For that reason, a program was designed where workers are trained in that area by the UANL.

That program has already trained eight classes in companies in the entire cluster and it has been very successful in CLAUT. It is also being replicated in the Electrical Appliance and Aerospace Clusters. Plans are underway for the program to be taught in the Agrofood cluster for hydraulic pumps.

“In addition, in the area of the development of suppliers, we have been given the task of evaluating and selecting national suppliers, especially suppliers in stamped parts and plastic parts”, indicated Aguilar.

Some of the main companies that form the cluster in this area are: Nemak, Johnson Controls; Vitro Automotriz; Xignux; International Navistar; Mercedes Benz; Denso; Carplastic; Takata; Metalsa; Quimmco; Anchor Lock and Ficosa.

Large network of suppliers, large cluster

At present, Mexico is the main supplier for the industry of electrical home appliances in the United States, Canada and Central America due to the large network of skilled suppliers in the production of plastic materials, and those involved thermodynamic and thermoelectrical processes and in metal printing, among others.

Nuevo León has become an attractive option for foreign companies seeking a profitable production and export platform in the electrical home appliance industry.

Reason why at at present, the economy in Nuevo Leon has a solid electrical Home Appliance Cluster in continuous growth. It is a network formed by more than 100 supplying companies that has permitted companies such as Whirlpool; Friedrich; Carrier, York; Phillips; LG Electronics; and Mabe, among others, to establish their operations in the State. That cluster was founded in December of 2006.

In addition, the productive chain of electrical domestic appliances has been strengthened, supported and formed by other industries, such as the metal mechanic, electrical and plastic industries, among others.

Industrial diversification, local competitive advantage

The State’s great variety of sectors helps its production, economy and participation grow within different markets.

“Nuevo Leon’s great advantage as far as clusterization is concerned is its industrial economic diversity. With more clusters, more economy is generated and sectors are specialized”, stated Pérez who added that “business activities have to form clusters. In this globalized world in which competition is more and more fierce, new work forms must be adopted and the triple helix is a source for it. Companies that do not get on this train run the risk of being left out of the Marketplace”, stated Pérez.

Reason why the creation of clusters more and more constituted a form of growth of industrial competitiveness of the State.

Other cluster also representantive in Nuevo León is the aerospace cluster created in July of 2004 is formed by 18 businesses, of which 14 are companies, 4 are academies and 2 are public agencies.

Among the most important and outstanding businesses that strengthen competitiveness in the regional cluster are: Frisa-Wyman Gordon; Doncasters; Decraine Aircraft; MD Helicopters; Bodycote and Jaiter, among others.

That cluster is primarily focused on serving innovation and technological development, attracting foreign investment, human resources and developing suppliers.

Today, the cluster is working on the development of AS 9100 in small and medium-sized businesses with 150 hours of consultancy.

“The object is to create processes in PYMES so they may also become a part of the sector”, stated Pérez.

The biotechnological cluster was founded in January of 2008. This cluster has a special health section, but it is also achieving an impact on the global economy in other areas such as the biofood, bioecology and biosafety sectors.

Fourteen companies participate in the cluster, among which are found: Merchant; Monsanto; Sigma; Novartis; Signux, as well as a growing group of businesses linked to the pharmacological sector.

Along with the development of biotechnology in Nuevo Leon, the Center for Biotechnology of the Tecnológico de Monterrey was begun as well as the Center for Research and Technological Development in the Area of Food and the construction of a tower for research in medicine and biomedicine at the UANL.

In 2009, it indicated its commitment of creating nanotechnological developments applicable to local and International markets. On June 9, 2008, it started the nanotechnological cluster (a science that deals with particles that measure one billionth of a meter).

The cluster’s main participants are: UANL, ITESM, Arizona State University, Center for Investigation on Advanced Materials (CIMAV); the Center for Engineering and Industrial Development (CIDESE); the Institute of Electrical Investigation (IIE) and 17 companies, among which are found Vitro, Sigma, Prolec, Metalsa, Cemex, Plásticos Rex, Viakable, Lamosa, Whirlpool, Ternium and Grupo Industrial Saltillo.

The cluster’s objectives are to develop human capital, to attract financing and to implement projects for new businesses with the application of nanotechnology.

On the other hand, the object of the Council for the Development of the Software Industry in Nuevo Leon is to support and participate in research, scientific and technological developments in any of their forms, to promote the software industry and information technologies in Mexico and in foreign countries, to form alliances and cooperative agreements with public and private companies and public and private institutions and with middle and higher educational centers, among many other activities.

It must be mentioned that one of the council’s most important projects is the development of human capital in the area of software. For that reason, it has created the Institute for the Development of Talent (IDETI) for the development of professionals capable of promoting the software industry in Nuevo León. This Institute is based on the model used by entertainment centers in India.

In the IDETI (which has a excellent proposals for bringing together industry and educational institutions) courses will be taught to standardize students from different local universities and technical schools. This cluster is formed by 22 businesses.

The Agrofood Cluster is formed by 31 participants, including 19 companies, 4 academies and 2 public agencies, 5 associations and 1 medical center.

Its working committees are centered on developing suppliers, on innovation and on transferring technology, organic agriculture, citrus fruits, standards and the certification of processes.

The Heath Cluster created in the 2005, has 20 members, including six hospitals, four clinics, four academies, and six public agencies that work in bioethics and education in quality and safety.