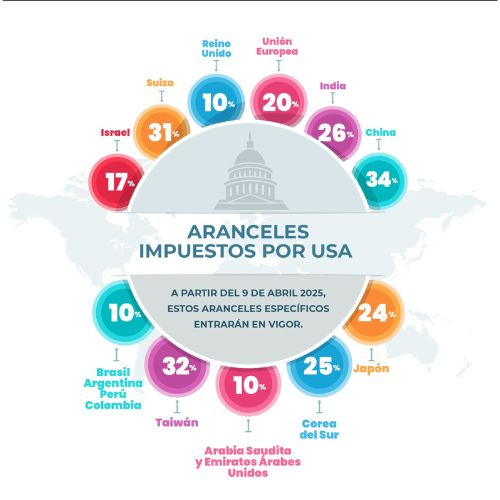

The manager highlighted that 75% of Riken Mexico's supply depends on Japan, where the company's origin is located, and the rest is national, from the United States and Canada.

The supply chain expert added that some of the products that Riken Mexico consumes nationwide are high precision packaging and machines.

"Many are machined, we are looking for suppliers that manufacture molds, we make the rings for the transmission, as they are classic we use some molds to make this manufacture, some pressing molds and other injection molds, so we are looking for mold suppliers", mentioned.

The purchasing and warehouse manager of Riken Mexico detailed that the company acquires sand for sandblast processes or aluminum oxides from suppliers located in the United States.

How to be part of their supply chain?

To be part of the Riken México supply chain, the national supplier must comply with certifications such as ISO and an audit is subsequently carried out, according to the purchasing specialist.

"We do the validation with an internal audit, we visit them, review and maintain a close process with the supplier, once the process is completed we let them work, if we observe any abnormality in mass production we go back to them and start over" he explained.

The manager said that the national supplier has areas of opportunity to improve on issues such as seriousness, compliance in delivery time and monitoring of payments; while on the subject of quality, he considered that it is good.