According to the Global Carbon Project, energy production currently represents around 86% of CO2 emissions, so how can we achieve this decarbonization objective when, for example, Mexico is dependent on hydrocarbons?

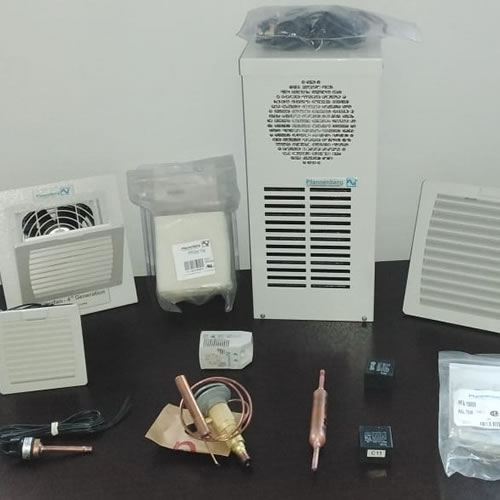

Through the union of the electrical and digital: Electricity 4.0, a term applied by Schneider Electric in all its solutions, which allows industries to be more sustainable, resilient, inclusive and efficient.

This smart energy management through Electricity 4.0 helps turn data into logical and meaningful insights to develop synergies between business consumers and energy professionals, while boosting energy performance.

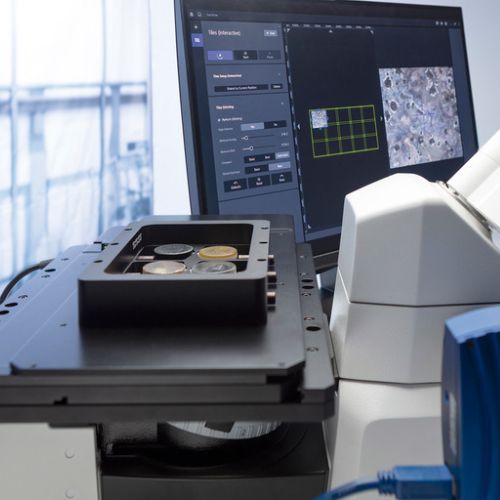

That is why a computerized management system is needed with the use of smart machines, computer networks, AI, devices, software and applications, designed to monitor and measure the energy consumption of businesses to understand how they use energy.

Subsequently, this will make it possible to control and optimize energy consumption. Digital innovation in industry makes the invisible visible, as it eliminates energy waste and promotes efficiency. This will reduce costs, but it also contributes to sustainability by reducing the carbon footprint.